Plc Alarms & Fault Handling - Practical Hands-On Virtual Lab

Last updated 2/2026

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz, 2 Ch

Language: English | Duration: 1h 3m | Size: 658.06 MB

Build alarm and fault logic exactly like used in industrial Programmable Logic Controller PLC systems.

What you'll learn

Design professional PLC alarm logic using ladder diagrams

Build latched alarms with proper acknowledgment and reset logic

Implement fault detection, counters, and automatic lockout systems

Create fail-safe safety circuits including overload and E-Stop logic

Develop complete industrial interlock systems used in real factories

Requirements

No advanced PLC experience is required.

Basic understanding of PLC ladder logic

Familiarity with digital inputs and outputs

Description

PLC Alarms & Fault Handling - Practical Ladder Logic

Build alarm and fault logic exactly like used in industrial PLC systems

________________________________________

Course Overview

Most PLC courses teach you how to start motors and turn outputs ON and OFF.

Very few teach you what truly matters in real industrial systems

Alarm handling, fault management, interlocks, protection logic, and safety design.

In real factories, equipment failures don't happen because someone forgot a timer.

Х They happen because alarms were poorly designed.

Х They happen because faults were ignored.

Х They happen because interlocks were missing.

This course teaches you how to design PLC alarm and fault logic the way it is actually done in industry.

This is a 100% practical course. No unnecessary theory. No slides full of definitions.

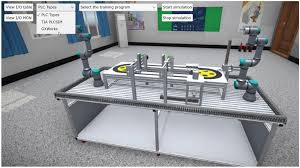

You will build real alarm systems using ladder logic step-by-step inside a simulated industrial environment.

________________________________________

What You Will Learn

Х Design basic alarm detection using AND/OR logic

Х Build latched alarms with proper operator acknowledgment

Х Implement time-delayed alarms to eliminate false triggers

Х Create motor overload protection logic

Х Design fail-safe Emergency Stop (E-Stop) circuits

Х Develop alarm priority systems for real-world operations

Х Implement fault counters with automatic lockout

Х Build intelligent auto-recovery logic

Х Create structured alarm event logging

Х Combine everything into a complete industrial interlock system

By the end of this course, you will understand how professional PLC programmers design alarm and fault handling systems in real plants.

________________________________________

Why This Course Is Different

This course focuses only on alarm and fault handling - the most critical part of industrial automation.

You are not just learning how to program.

You are learning how to think like an automation engineer.

You will understand

Х Why false alarms are dangerous

Х Why latching is essential for safety

Х Why fault counters prevent catastrophic failures

Х Why interlocks protect equipment and people

Х How proper alarm design reduces downtime

These are job-ready skills used in

Х Manufacturing plants

Х Oil & gas facilities

Х Power plants

Х Water treatment plants

Х Process industries

________________________________________

Who this course is for

Electrical Engineers

Instrumentation & Control Engineers

PLC Programmers

Maintenance Engineers

Technicians working with industrial systems

Students who already understand basic PLC ladder logic