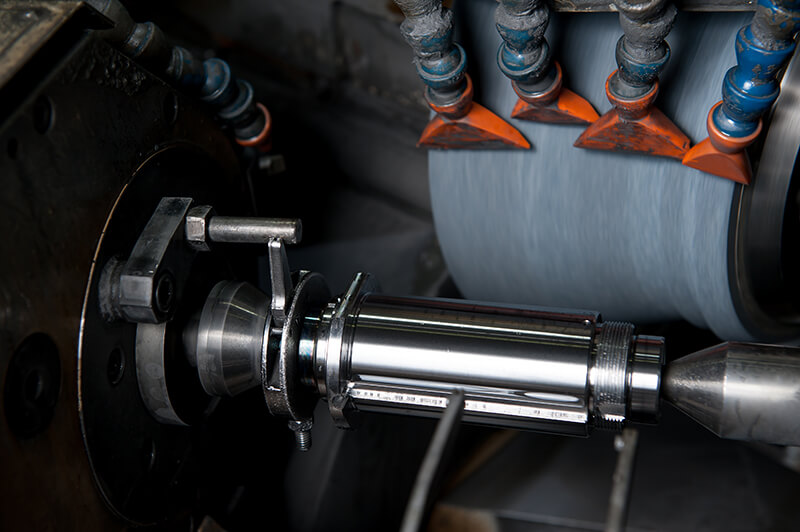

Od Cylindrical Grinding: From Drawing To Finished Part

Od Cylindrical Grinding: From Drawing To Finished Part

Published 1/2026

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz, 2 Ch

Language: English | Duration: 1h 1m | Size: 651 MB

A practical approach to plunge, angle plunge and traverse grinding

What you'll learn

Perform cylindrical OD grinding using the main methods: plunge grinding, angle plunge grinding, and traverse grinding

Select the correct grinding wheel and understand the key factors influencing wheel choice

Select appropriate dressing tools, understand and calculate key dressing parameters

Calculate all key process parameters for each grinding operation, including speed ratio, material removal rate, infeed rates, and traverse feed rate

Requirements

Basic understanding of cylindrical grinding processes or prior experience in a grinding environment

Ability to read technical drawings and understand basic tolerances

Description

This course focuses on OD cylindrical grinding, following the complete process of grinding a real industrial part from technical drawing to finished result. The entire training is built around a practical example, showing how individual decisions are connected and how a complete grinding process is developed step by step.Instead of relying on trial-and-error approaches, the course explains how grinding decisions are made in practice. You will see how drawing interpretation, grinding wheel behavior, coolant application, dressing, workpiece setup, programming and parameter adjustment influence one another within a real grinding process.The course covers:How to read and interpret a technical drawing How to identify which surfaces require grinding and how to structure the operations logicallyHow grinding wheel characteristics influence cutting behavior and process stabilityHow coolant application and jet velocity affect heat generation and grinding resultsHow dressing tools and dressing parameters influence wheel performanceHow to correctly set up the workpiece, establish X and Z zero positions, and verify the available stock allowance before grindingHow to program and apply different grinding strategies, including plunge grinding, angle plunge grinding and traverse grindingHow to evaluate grinding results and adjust key process parameters such as wheel speed, depth of cut and feed rates when initial settings do not produce the expected outcomeAll examples and explanations are based on practical shop-floor experience and realistic industrial conditions, not idealized textbook cases.This course is intended for CNC grinding operators, technologists and engineers who already have basic grinding knowledge and want to better understand how and why OD cylindrical grinding processes work in practice, with the goal of achieving more stable and predictable results.The explanations focus on practical decision-making on the shop floor, helping reduce uncertainty, scrap, rework and unnecessary adjustments during real production grinding processes.

Who this course is for

Cylindrical OD grinding operators

Early-career machinists or technicians

Manufacturing engineers and technologists